INTRODUCTION

PROCESS FOR DEVELOPING RAW MATERIAL ZONES ACCORDING TO ORGANIC PRODUCT STANDARDS

Developing organic raw material zones is a core strategy of Bambooleaves Vietnam to build a sustainable value chain, ensure the highest quality of output products, while contributing to environmental protection, nature conservation, and sustainable livelihoods for mountain communities.

– Seedling Preparation: Conducted in certified nurseries. Seeds are selected from healthy, naturally grown mother plants with high productivity. Seeds are treated using natural methods, without chemical germination stimulants. The planting medium is a mix of clean soil, organic compost, and biological humus, ensuring a loose texture and rich nutrients. During the seedling stage, plants are watered with mist sprayers to maintain optimal moisture, shaded from sun, wind, and protected from insects with nets to create the best growth conditions.

– Planting: After 2 – 3 months, when seedlings reach a height of 30 – 50 cm with 3 – 5 true leaves, they are transferred to natural planting areas. Planting sites are carefully selected, prioritizing areas at elevations of 700 -1,200 meters above sea level, with cool climates, high humidity, loose and organic-rich soil, good drainage, and stable moisture. Before planting, the soil is manually cleared of weeds and enriched with green manure. Plants are arranged in orderly rows, ensuring proper spacing for natural growth, facilitating care, and future harvesting.

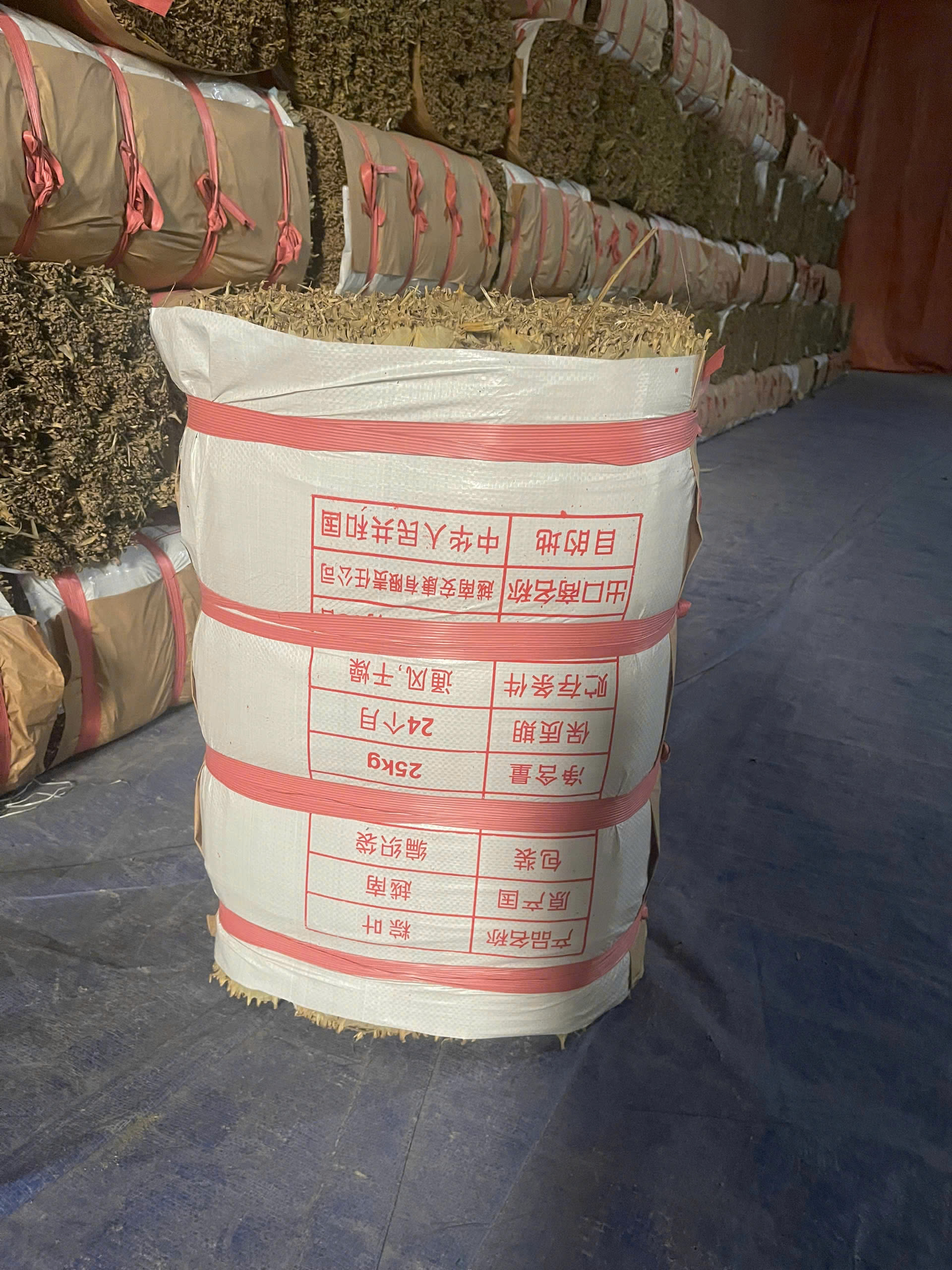

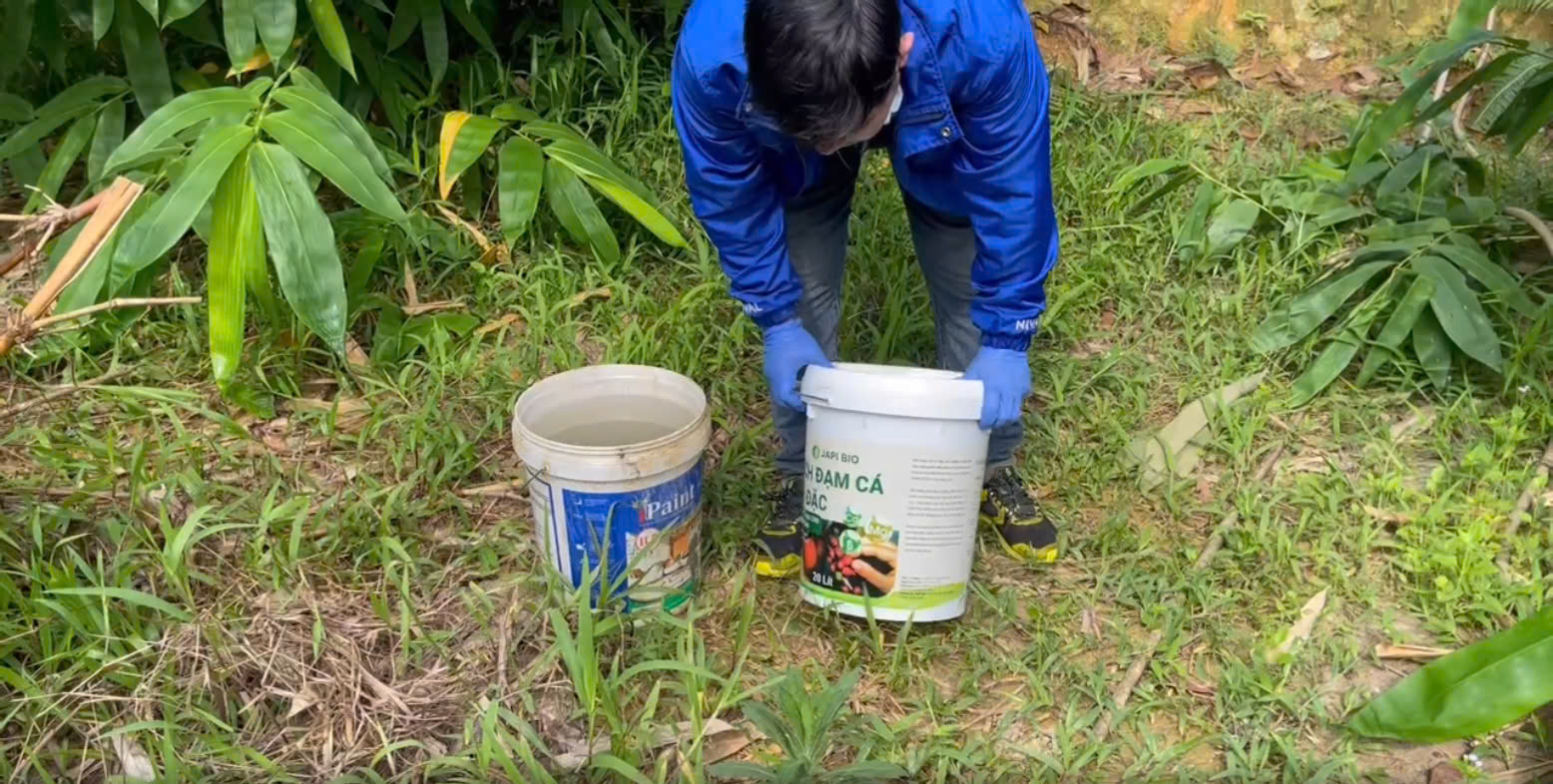

– Plant Care: Organic farming practices are strictly applied during care. No chemical fertilizers, inorganic fertilizers, or synthetic pesticides are used. Instead, the following are employed: fish emulsion, biological preparations, microbial compost, organic compost, and vermicompost; herbal pesticides made from fermented garlic, ginger, and chili to control pests; and wood vinegar for mild antibacterial, antifungal properties and growth stimulation. All materials used must have clear origins, be certified as compliant with organic standards, and be meticulously recorded in a cultivation log (including usage dates, types of fertilizers/pesticides, quantities, and sources) to support traceability and product certification. Weeds are periodically removed by hand or simple tools, and mulching with straw or dried leaves is used to retain moisture and reduce weed regrowth.

Irrigation water is sourced from natural mountain springs, stored in artificial reservoirs, and distributed through pipelines and mist sprayers to ensure consistent moisture, especially during dry, sunny weather.

The entire production process is closely monitored by a team of technicians and agricultural experts. As a result, the plants grow and develop well, producing high-quality leaves with a distinctive fragrance that meet the stringent requirements of export markets.

Bambooleaves Vietnam’s model creates stable livelihoods and promotes sustainable development for mountain communities.

Read More